Sometimes its pitting, corrosion as the problem. Sometimes it accidents and unforeseen dents, crashes and gashes.

We can weld on new patches over the top of corrosion and then you have brand new metal in its place the same thickness as the original.

Sometimes we cut out the damaged area, and then weld in in new aluminum. It varies from tank to tank, from damage type to damage severity.

We pressure test every fuel tank we work on before we consider it done.

I make it look easy, but there is a lot of hidden tricks and skills necessary in order to be successful. On most of my pages I explain in depth what I'm doing.

But here I'm going to keep my secrets. I'm not going to teach my competition how to do it right. Sorry.

But if it arrives with liquid fuel in it, even a small amount, be prepared to spend a lot more money. I am not interested in cleaning out tanks for lazy owners.

If you need a new custom boat/marine fuel tank, or any other type, we can fabricate it for you to your dimensions and weld on any fittings, threads, elbows that you desire.

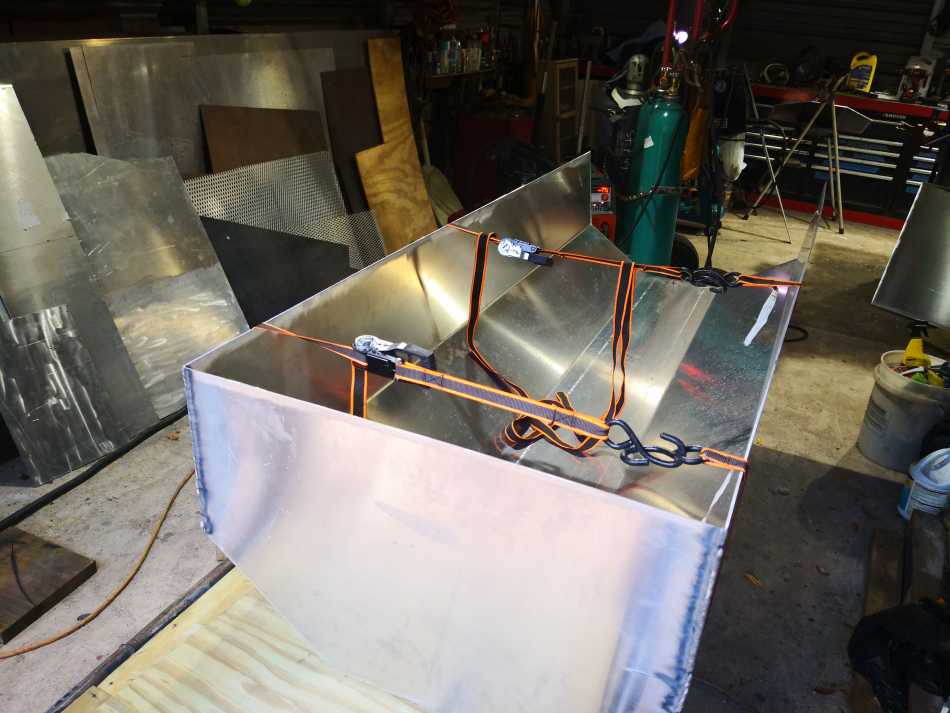

Below you can see a aluminum tank belly about to be built. I had it pre-bent to match the customers old tank so it would fit in his commercials fishing boat exactly as the old corroded tank did.

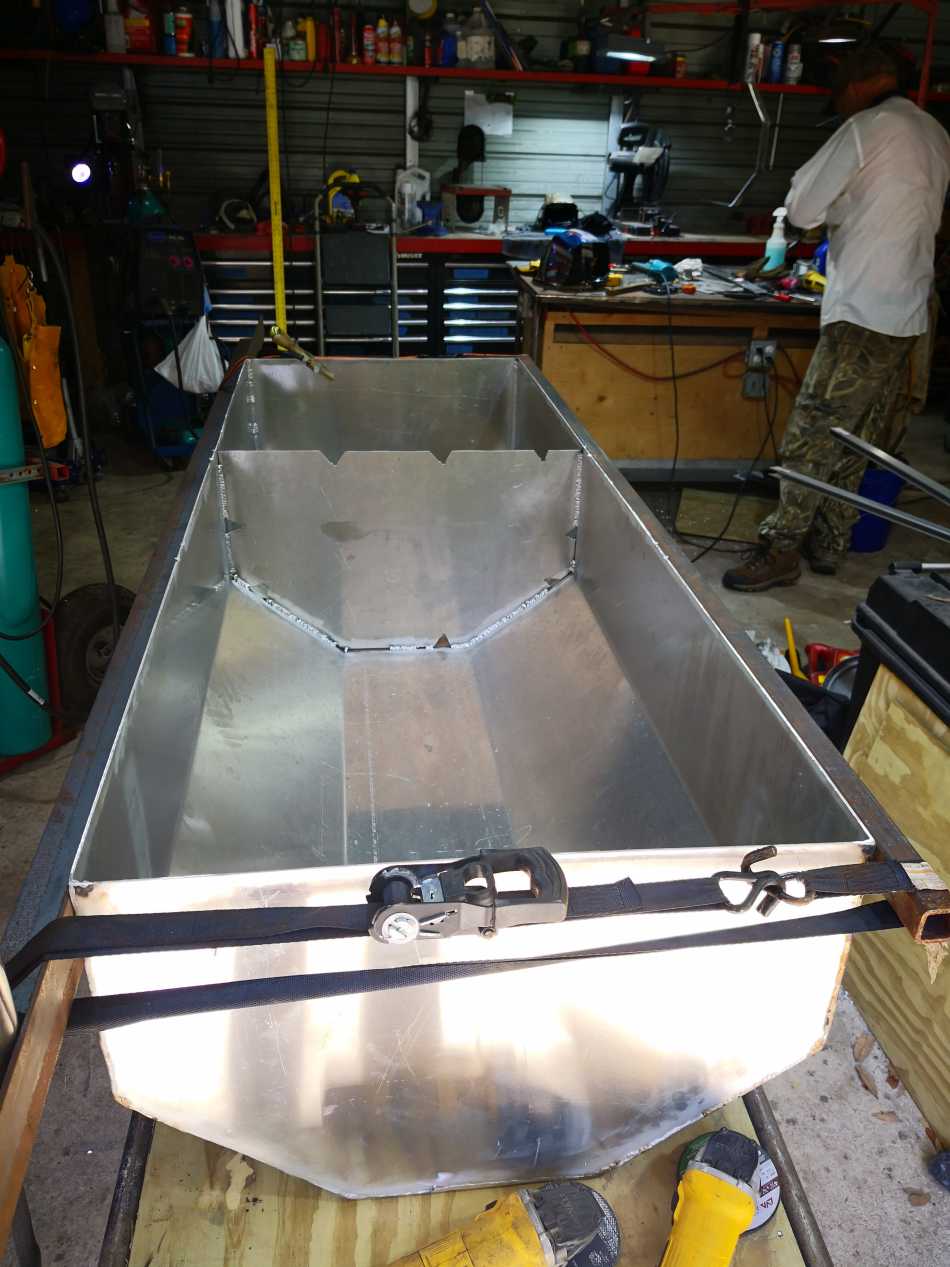

Then I weld on the end caps. It must be a precise fit or the top wont fit properly later on.

I weld it all the way around and flip the tank to get the angles just right for the best welding.

See that line across the middle of the tank. Thats the baffle already welded in. That line shows how good my weld penetration is as the melt zone reached the outside of the tank.

After welding we wire brush the welded beads to remove any soot and examine the welds to make sure its all perfect. Once in a while there is a piece of weld not perfect and I grind it out and reweld it.

On a fuel tank going below the boat floor, anything less than perfection is just not good enough. It may not be perfect the 1st time I weld it, but it will be perfect when I'm done with it.

We also build and repair steel fuel tanks.