Build page 1. BBQ offset smoker built in St Augustine.

Build page 2. BBQ offset smoker built in St Augustine.

THIS PAGE IS Build page 3. BBQ offset smoker built in St Augustine.

The doors of the metal box being converted into a smoker, had vents in them. Jamie welded a patch closing up the vents. No that is not my welding. But that is very good welding considering Jamie just learned. It was his 2nd or 3rd day.

But the weld on the bottom patch came out very good.

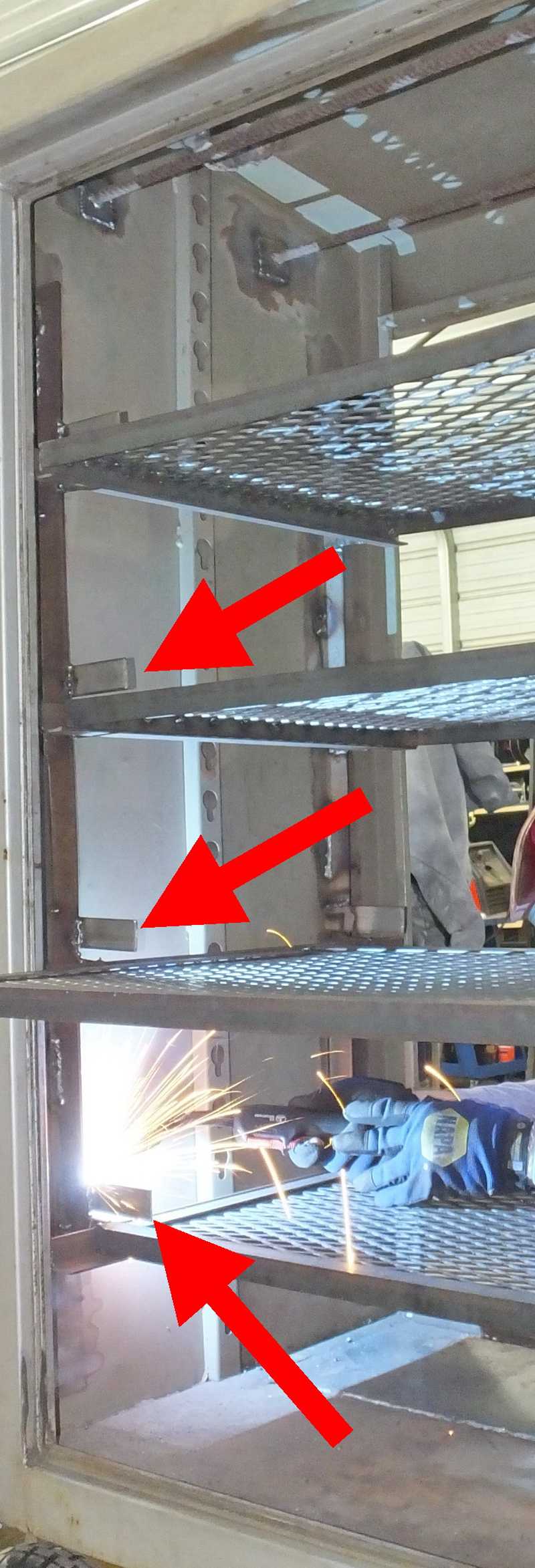

Now you can see from the inside of the smoker, the heat and smoke doorways that lead from the firebox into the smoker chamber. Jamie chose this design. The red arrows are his patches closing the old vent flow.

The weld heat from the patch welding caused the doors to warp and bend enough they didn't close tightly anymore.

So we welded bars in them forcing the doors back into shape and they closed nicely after that.

It didn't take much at all to straighten out the doors. But figuring out the solution caused us to ponder a while and scratch our heads before the light bulb came on.

Now its time to start cutting the rack slides so the cooking trays can slide in and out.

Now Jamie is welding on perimeter frame to make the expanded sheet metal rigid enough for holding 60 lbs of meat on each rack if so chosen. These are the cooking smoking racks.

Now Jamie is teaching my photographer how to weld. She is usually behind the camera taking pictures for this website.

Say Hi to Patty.

We were having way too much fun. Sometimes this is more of an adventure than a job.

Doesn't she look too cute with that welding helmet and way too large welding jacket on?

No that's not really beer in Jamie's hand. Its HEINEKEN. Its 10 Pm. Work is over and now its all play.

Patty wouldn't let me put in the other cute pictures of her on this webpage. I didn't really think she would follow through on her threats, but just to be on the safe side...

BELOW: Jamie is welding on the inside of the smoker. Its fascinating to watch the outside just light up and begin glowing red hot for no visible reason at all.

First the paint would just start to blister and bubble.

It was fascinating to watch.

Now we are building slide rails so the meat racks can slide in and out. We thought it would be easier sliding the meat out to us rather than us reaching into the cooker to handle it.

Now the first meat racks slide in and out exactly as planned. But what if he pulls a rack too far out? Does all the meat tumble to the ground?

We are hiding our beer in this picture so you cant see it. We are pretending to be sober. That's me, Chris Van and Jamie the owner of this offset meat smoker BBQ cooking wood fired grill. Jamie is my customer in case you didn't catch that.

So I convince Jamie we need to weld some tabs on the racks so they cant accidentally slide too far out.

The tabs allow you to pull a cooking tray all the way out and it cant tip/fall down accidentally. Now you can pull a tray totally outside of the cooker, out of the heat and load/unload it conveniently.

Eyeballing our work and being filled with joy and pride at our accomplishment.

Its great to build something that will last and function for forty years.

Success celebration with special homemade Brandy shots in Gold cups.

This smoker took us four evenings plus a Saturday to build.

Now Jamie is loading it up on the trailer for the haul back to his home. Now the welded on tie down strap points come into valuable play.

Its been an adventure. Now its the smokers time to begin its journey of a new life cooking at large parties.

We didn't get pictures of the handle build. I built it a "T" pull handle so the meat smoker could easily be pulled around. You can see it folded up on the front out of the way.

Good bye meat smoker wood fired cooker built here in St Augustine Fl. See you at your next party.

The finished painted page BBQ cooker smoker.

Build page 1. BBQ offset smoker built in St Augustine.

Build page 2. BBQ offset smoker built in St Augustine.

THIS PAGE IS Build page 3. BBQ offset smoker built in St Augustine.