|

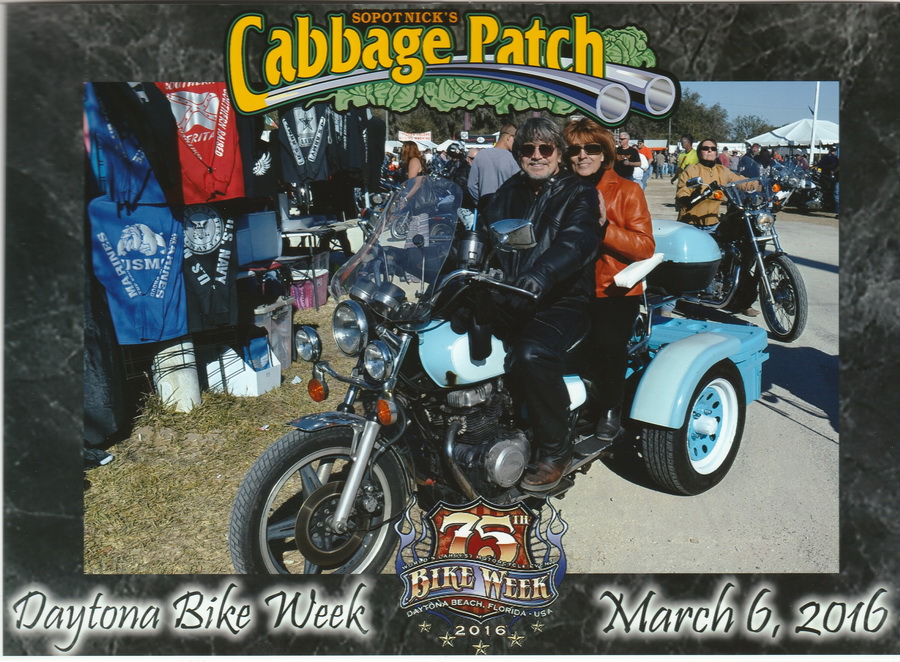

This is my trike motorcycle. It had a normal foot rest, but I wanted more. I wanted an extended very comfortable leg rest and more foot peg rests further forward.

Here is where I thought it should have an additional leg rest so I could straighten my legs and ride in luxury.

Below is how I wanted it to turn out.

So based on where I thought an additional leg rest ought to be, I designed and built the leg rest out of 304 Stainless Steel. I wanted the chrome look without rust and no maintenance.

It turned out perfect. Below are the fabricating pictures of building new foot pegs and leg rests on my custom trike.

After and then before.

After and then the beginning.

Getting the alignment of the new foot pegs is critical. Because after its welded in, the new leg rest will be built atop of it.

And the alignment of one foot peg must be a perfect match to the other side even though they are not continuous, they are to appear that way.

To get the height match perfect, I had to put wood shims under the tube atop of the jack stand.

Now the stainless steel tube is welded to the motorcycle frame.

The welding heat caused the frame bracket that was not bolted closed, to open further. But once I put the bolts back in, the two stainless tubes came back into perfect alignment.

Quick test and approval. Feels just right for another forward foot peg. Now build the leg rests atop of it.

Now I begin cutting the stainless tube pieces to fabricate the upper leg rest framework.

I don't want normal looking 90 degrees. I want it nicer looking so I cut 45 degree pieces to weld inside and remove the sharp angle and soften it up.

We are able to do very precise work when the budget allows. On this project I am after medium quality, not high nor low.

The top corner half I was able to build on my bench for easier access. But the bottom corner half will have to be built on the trike .

I have clamps and wood blocks holding it in place so I can connect the top half to the bottom half. This allows me to play with my alignment until I'm satisfied and make it permanent.

There is my good fit and the perfect hang down for joint welding. Remember this is only medium quality.

For a stronger weld I let the vertical tube hang slightly below the horizontal tub so I have plenty of overlap for a strong weld.

Now the two halves are welded together. The upper half has already had its welds ground down and semi polished, but not to perfection, but to nice looking.

You can see the contrast between the upper cleaned welds and the lower raw welds.

Same on the other side. Haven't yet cleaned up the lower welds. That's next.

I debated welding on end caps and the time it would take versus inserting plug caps.

Now I have a couple of nice, classy, neat clean looking, highly comfortable leg rests toped with white soft cushy leather.

I have wanted that for so many years. I was so happy to finally have it.

You see, this trike has an automatic transmission and I never have to take my legs off the rest for shifting. So this is long lasting comfort.

You can see the bracket welds under the padding I did not clean up as no one can see it unless their head is low to the ground as the camera is.

Its stainless. It wont rust. That's enough for me in this situation.

Now I have end caps in the holes. That suits me fine. They wouldn't be suitable in a hand railing job, but they are fine for an old 1982 Hondamatic 450.

I could have chosen to clean the welds to perfection and make them 100% invisible. But that was never my goal.

My goal was never rust, shine like chrome, never paint, unique and clean looking. And utmost comfort. Well achieved.

The top weld was not in a spot where one could see it, but the bottom was. So you can see I treated them differently.

The camera flash lighting showed imperfections you can't see in real life. It looks much better in person.

This is a 1982 antique with 3,600 original miles. Honda 450 automatic transmission custom built trike.

If you need stainless steel work done, whether hand rails, sail boats, commercial kitchens, boat T tops, give me a call for a free estimate.

We have a quality level to match your budget. This job was only medium quality. We can be more budget oriented, or more elaborate. You decide. |

Remember, I work by appointment only, so be sure to call and schedule us. 904-638-8338 Call me, 8 Am to 9 Pm, any day of the week.

Questions or comments, feel free to call.

Our company name is "After Hours Welding & Trailer Repair." We serve all of St Johns County and surrounding areas.

We do very low-priced, competent & quality work, by appointments only any day of the week. Yes weekends and holidays to.

Call anytime thanks to the magic of cell phones, I probably am available to answer you're questions.

Without hesitation, call me at 904-638-8338 I'll be happy to give you the information

needed in order for you to make a wise, informed purchasing decision.

|

St Augustine Florida

St Augustine Florida

St Augustine Florida

St Augustine Florida