|

What is an escape room?

A new form of themed entertainment popping up across the country involves players willingly getting trapped in a room. To get out, they must solve a series of puzzles.

They are called escape rooms, and they're pioneered by entrepreneurs who've created a growing business with an unusual business model.

This is a mobile escape room, tractor trailer we built for a customer. The portion this page will highlight is how we attached the generator to the tractor trailer.

Initially it was discussed to build a rack or cage the generator could ride in so it was always with the tractor trailer and didn't need to be hauled separately as was the customers first idea.

Sounds good but how do you add gas to the generator? If the generator is mounted below the trailer and the gas cap is on top of the generator, you cant get to the cap unless you remove the generator from the rack each and every time you need to add fuel.

And the generator weighs 250 lbs. So you need two strong men to lift and remove it from the rack every time you want to add fuel? And lift it again to put it back?

What about safety so the generator is not stolen when you turn your back?

This is how I solved all their problems. The generator needs to be mounted behind the tires, below the mobile escape room floor.

That black generator is the one we are going to mount in a fabricated cage.

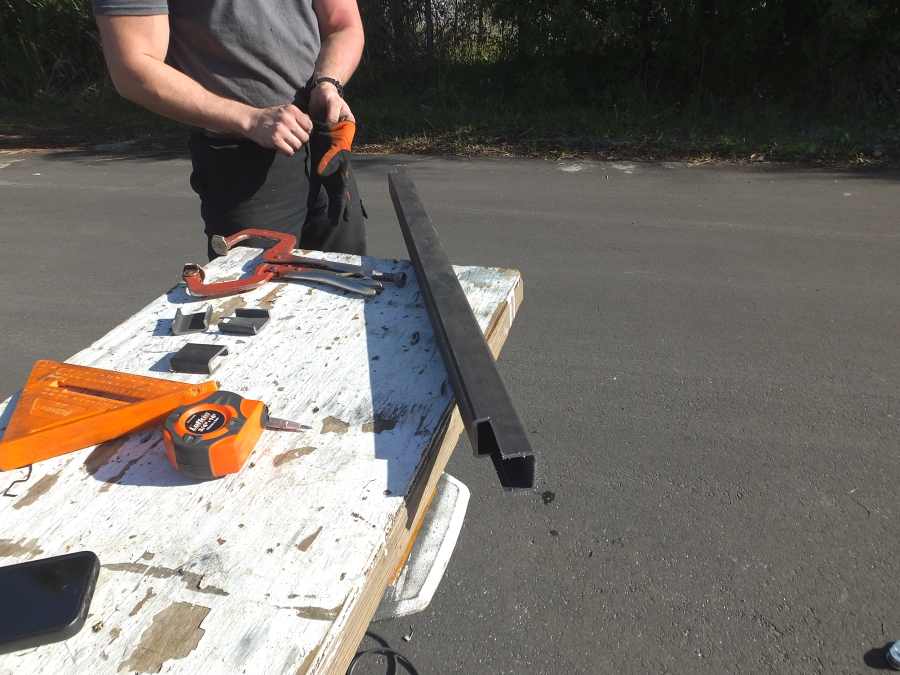

So here is the beginning of the rack we are fabricating out of structural steel.

The rack is being fabricated onto a long slide, like a drawer would slide out. So it can be put away and run while making electricity, and pulled out to fill with fuel or other maintenance.

Since I have a background in engineering and design before I opened my welding shop, I am highly talented and adept at creating solutions to problems.

So the 80 pictures below, is what I designed and then fabricated and welded.

That's 3/16th thick wall tube cut to fit precisely. Precision performance requires precise fit ups.

But I don't want the drawer to slide, that's too much friction. I want the drawer to roll on rollers so its easy and effortless.

So my helper is welding special rollers onto the support arms that will hold the drawer in the cage, in place under the mobile escape room floor, below the trailer.

Each roller can hold 3,500 lbs. We use four of them.

No weak screws or bolts here. This fabrication is being welded together so its super strong.

Now you can see how the generator rack drawer fits into the rollers designed to hold the drawer in the cage, in perfect place with lots of strength.

We continue precision cutting pieces of steel to build the next phase.

Long steel cut and welded together can build about anything.

Look closely at the upper and lower rails. They will act like a track within inner and outer train wheels.

But the upper and lower track is pinned/trapped between the wheels/rollers. The only movement allowed is forward and back, or you might say, in and out only.

And its in and out action is very smooth and easy while moving 250 lbs on a 48" in and out travel range.

And we have to mount the rack/drawer/cage under the tractor trailer in such a fashion that it cannot be stolen but is easy to access.

We put it together and test our fit of everything. We make adjustments until its perfect. When we are satisfied, we finish welding it permanently together.

Its designed to be welded to the steel beams underneath the trailer. Now we test its fit.

We jack it up to make sure the suspension arms will match the trailer beams perfectly.

The rack and cage weighs close to two hundred pounds. Every piece we add, it gets heavier and heavier until we are no longer willing or able to pick it up ourselves. Ok, call me lazy, but I don't want my floor jack to get lonely do I?

The fit is good. So now we finish the cage aspect of the sliding drawer. The drawer holds it and the cage in protection against theft plus its specifically designed to double as a sound barrier.

With the generator being immediately underneath the mobile escape room floor, we don't want all the noise coming up through the floor into the inside. We are trying to keep it quiet inside as best we can.

The cage/sound barrier is made from 1/2" plywood laminated to 1/2" concrete hardy board. 1" of barrier that is fire proof and is aimed at reducing 70 percent of the noise that is generated from the generator.

We can't block 100 percent of the noise because we can only build 5 sound proof walls and not 6.

One side must be left open for air circulation so the generator can stay cool while in operation. If we made a 6 sided box, the generator could not breath, and would overheat.

See the hole the red arrow is aiming at? The back side of the generator has a muffler and this is exactly where the exhaust is aimed out at.

See those three red arrows pointing at the corner, they are pointing at the padlock hasp that will prevent the drawer from being rolled out without authorization. To stop thieves from stealing the generator.

When the drawer is fully rolled out, its easy to remove the generator from the drawer for maintenance or repairs if necessary.

The generator cage welded and fabricated into this mobile escape room, rolls in and out as easily as we had hoped for. It behaves exactly as I designed and engineered it to.

Now you can clearly see how when the lock hasp is engaged, it will prevent the drawer from being rolled out.

Look close how the top of the generator nearly touches the roof of its cage. It has zero room to go upwards. The generator CANNOT be removed from it's drawer unless it's lifted upwards 6".

The generator cannot be lifted upwards unless the drawer is rolled out so the generator is not in the cage any more. The drawer will not roll out unless its unlocked.

You can not pull the generator out of its cage while the drawer is locked in place. It may look wide open, but you can't take it and go unless you have the padlock key.

This is the whole point of the roll out drawer. So you can pull the generator out easily when you need to add fuel to its top mounted gas tank. And easily put it away when your done.

To stretch their budget, the customer wanted a rough finish, not a expensive fine finish. Meaning: The customer wanted to do all their own painting and other finishes this Mobile Escape Room was to receive.

They only wanted me to do the parts they could not do themselves. They saved a good bit of money this way.

I still painted the metal so the customer had time to get around to the final finishing later. I didn't want it to rust. My pride was involved.

Plugged in and running, operating the two Air Conditioners and lights we installed in this Mobile Escape Room that we built.

If you want a mobile escape room designed, fabricated and fully built, or a generator vehicle mount made, or any welding and fabrication in general, I will be happy to give you an estimate.

My specialty is making my customers happy.

|

Remember, I work by appointment only, so be sure to call and schedule us. 904-638-8338 Call me, 8 Am to 9 Pm, any day of the week.

Questions or comments, feel free to call.

Our company name is "After Hours Welding & Trailer Repair." We serve all of St Johns County and surrounding areas.

We do very low-priced, competent & quality work, by appointments only any day of the week. Yes weekends and holidays to.

Call anytime thanks to the magic of cell phones, I probably am available to answer you're questions.

Without hesitation, call me at 904-638-8338 I'll be happy to give you the information

needed in order for you to make a wise, informed purchasing decision.

|

St Augustine Florida

St Augustine Florida

St Augustine Florida

St Augustine Florida