|

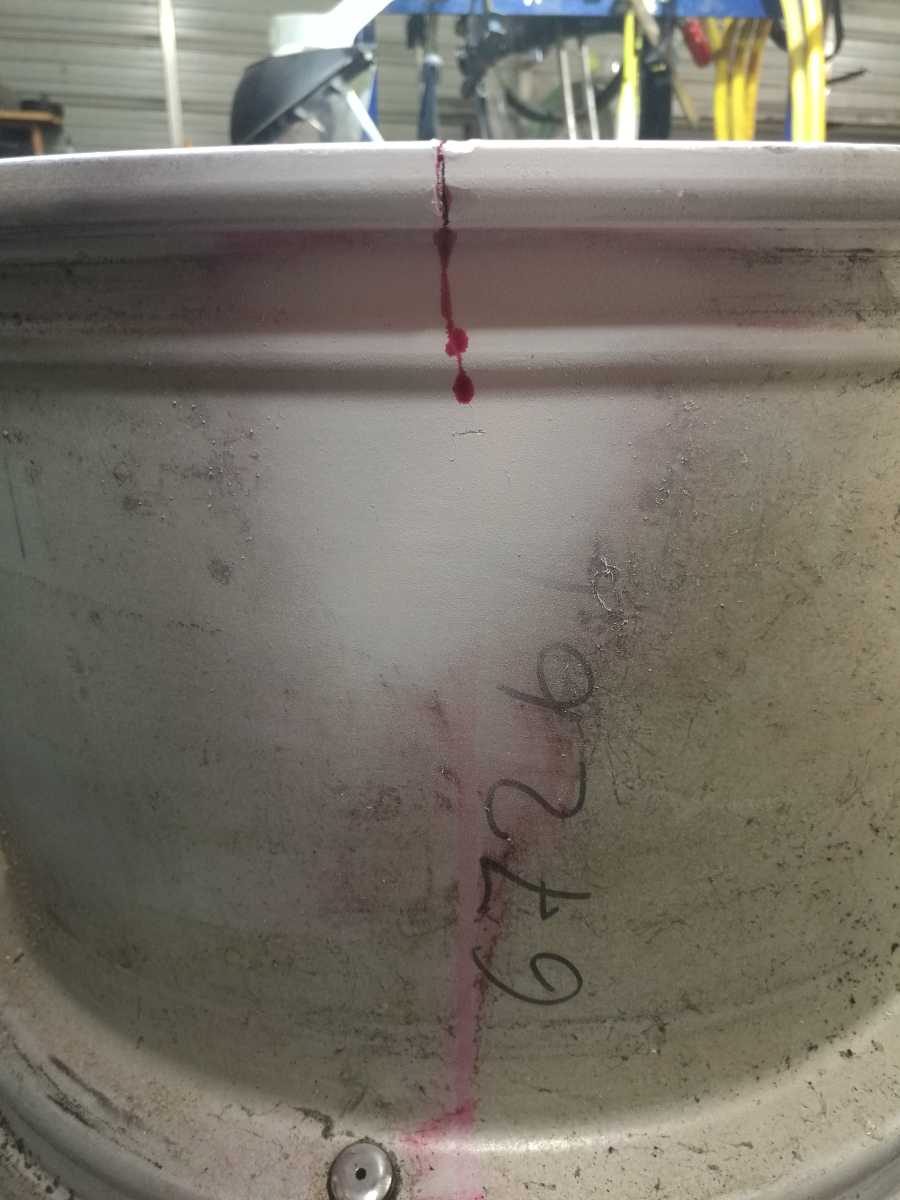

This wheel is from a 2002 Porsche.

They don't make this exact wheel any more. This wheel developed a crack and would not hold air any more.

I probably don't have to tell you, flat tires and fast cars are not a good mix.

Some of the crack was visible, but I suspected it went further than the eye could see. But how much further and in what direction?

I coat it with a special chemical that is absorbed into the very thin cracks. Then I put it into a special ultrasonic sound wave oven.

The ultra sonic sound waves effect the chemical differently inside the crack than it does on the outside of the aluminum.

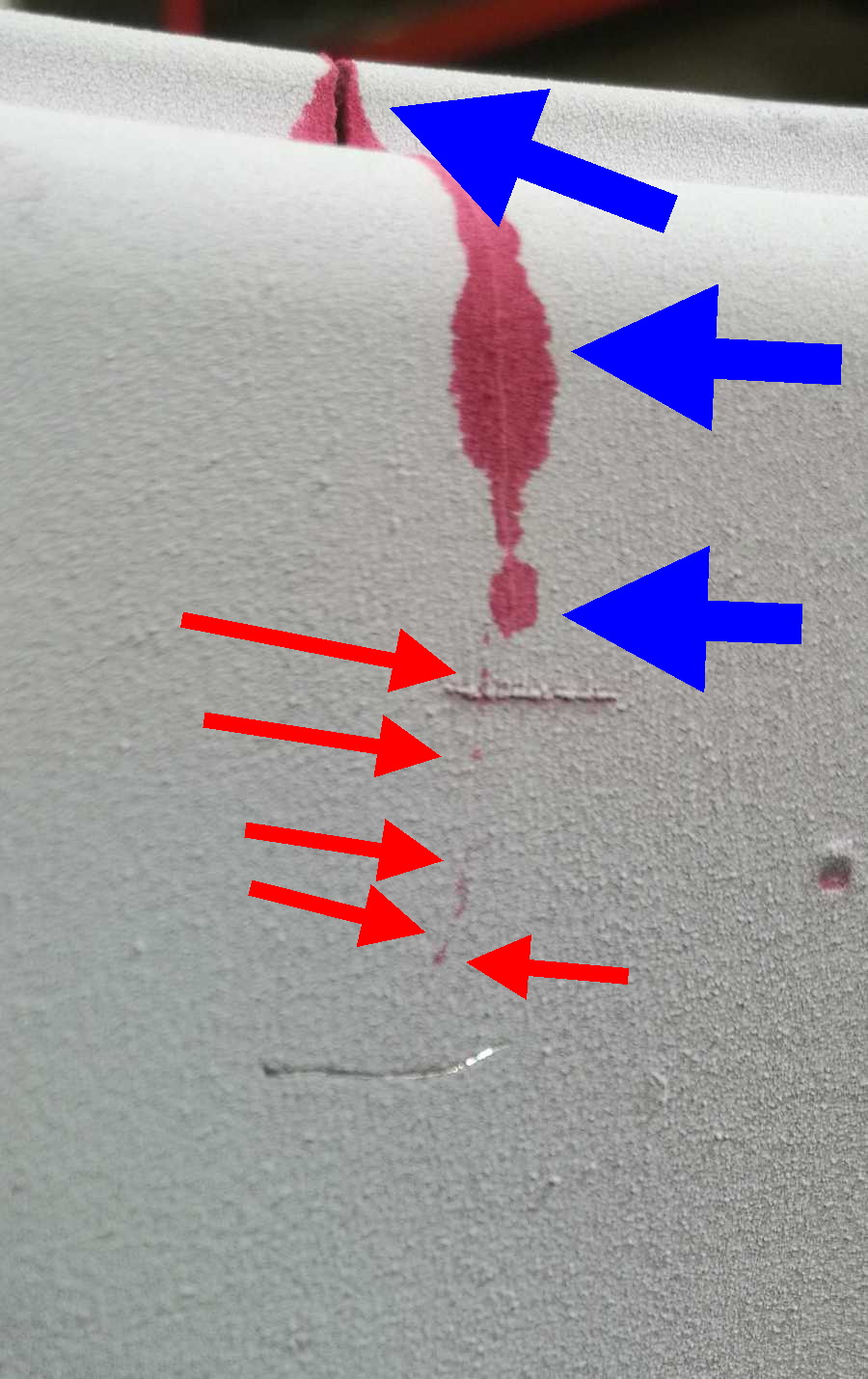

The chemical boils inside the crack and changes color. This red color shows me the extent of the real crack that the naked eye can not see.

BELOW: The blue arrows represent the crack we could see with our eyes.

The red arrows show you the additional crack our eyes could not see.

The red arrows, the crack was not fully developed, but in the process of beginning to rip. Now I know with precision exactly what area needs repairing.

One of my secrets of success that I'm willing to share with you, AND MY COMPETITION THAT READS THIS, is that all the bad metal needs to come out of there. I need a void where I can put back perfect virgin aluminum that has never been stressed before.

Now I weld in new virgin aluminum and fill that void to over flowing. The extra aluminum although momentarily unsightly, is fine at this point. Not pretty, but very strong. And what special type of aluminum alloy I use I will keep secret.

Some of that extra aluminum must go away, and some can stay. The more metal, the stronger it is. So if it wont be in the way, I'll let it stay.

But some of that extra aluminum must leave. I need to recreate the contour of the rim where the tire bead will seat against the wheel. And this part must be perfect if the tire is to hold air and not leak.

So I must remove some metal, remove some strength. So I bring it back to the dimensions the manufacture made it to. But it's still stronger than original because of my special alloy I used to replace the bad metal with.

Don't let the shiny light and shadows fool you. It's perfect.

The wheel is still dirtier than sin and needs cleaning desperately, but hey, that's not my job.

ABOVE: Before the contouring is complete.

BELOW: Contouring is nearly finished.

You can see the areas where the extra metal is not in the way of where the tire will seat. So it can stay and deliver extra strength.

Its easy to balance out. And there is no point in removing it. It sits inside the wheel in the back way under the car and it can't be seen from the outside.

Here is a different wheel repair.

This guy loved his Cadillac. He was proud of his wheels. They were custom and very expensive.

But they were discontinued and he could not buy just one. He would have to buy a whole set to make them match, and of a different style. Big bucks for something he didn't want.

The wheel cracked a month before and he had a different welding shop repair it. One month later it cracked again and let all the air out.

NO! I didn't do the original weld.

But this time he did his research and decided to bring it to a expert and pay to get it done right.

|

Remember, I work by appointment only, so be sure to call and schedule us. 904-638-8338 Call me, 8 Am to 9 Pm, any day of the week.

Questions or comments, feel free to call.

Our company name is "After Hours Welding & Trailer Repair." We serve all of St Johns County and surrounding areas.

We do very low-priced, competent & quality work, by appointments only any day of the week. Yes weekends and holidays to.

Call anytime thanks to the magic of cell phones, I probably am available to answer you're questions.

Without hesitation, call me at 904-638-8338 I'll be happy to give you the information

needed in order for you to make a wise, informed purchasing decision.

|

St Augustine Florida

St Augustine Florida

St Augustine Florida

St Augustine Florida