|

Below is a Aluminum AC Condenser, also known as a radiator and a heat exchanger is the most proper name. In this picture, you can see the damage to the coils on the top right.

But actually its top right because we have flipped this radiator upside down so the damage is now at the top. So you are actually looking at it now upside down.

This Aluminum Condenser Radiator costs $1,000 brand new, and it is new, but it has a leak due to an unforeseen accident that damaged one little vein.

To order a new one will take two weeks of shipping to get it in stock. The AC Company that was called to get the Air Conditioning up and running again, knew that Condensers have no history of being repaired when they leak. Its commonly thought of as a waste of time and money.

But two weeks was a long time for no AC while they waited for a new one. They decided to see if they could find some expert that could maybe fix it. They began calling around and found me.

I told them there was an 80% chance that I could. I know every other welder will tell them there is a 100% chance that it cant be fixed.

They aren't really telling you if it can be fixed, they are telling your their skill level, and mine just happens to be different based upon my past record of successes.

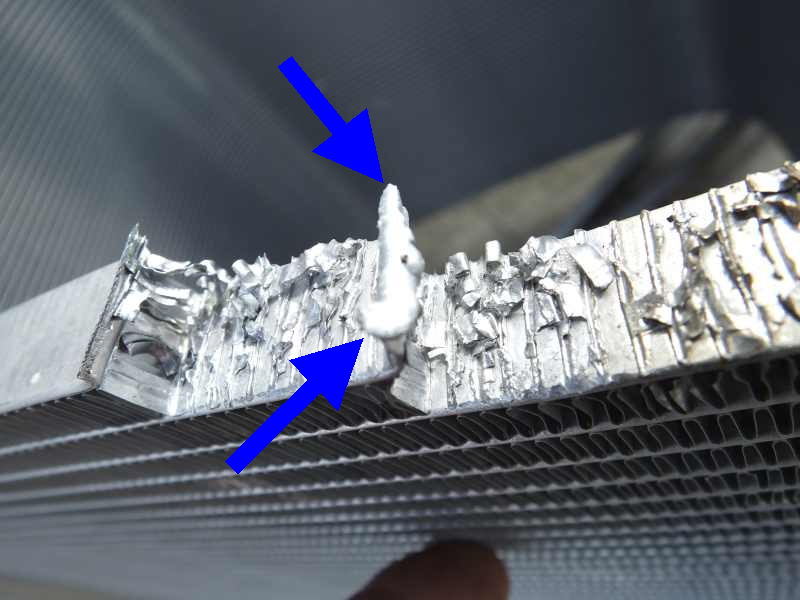

Below you can see the two visible cracks allowing this aluminum radiator to leak Freon out. But I cant work with it while the hole is at ground level. That's too low for me to bend over, so we flip it upside down bringing the leak to the high side.

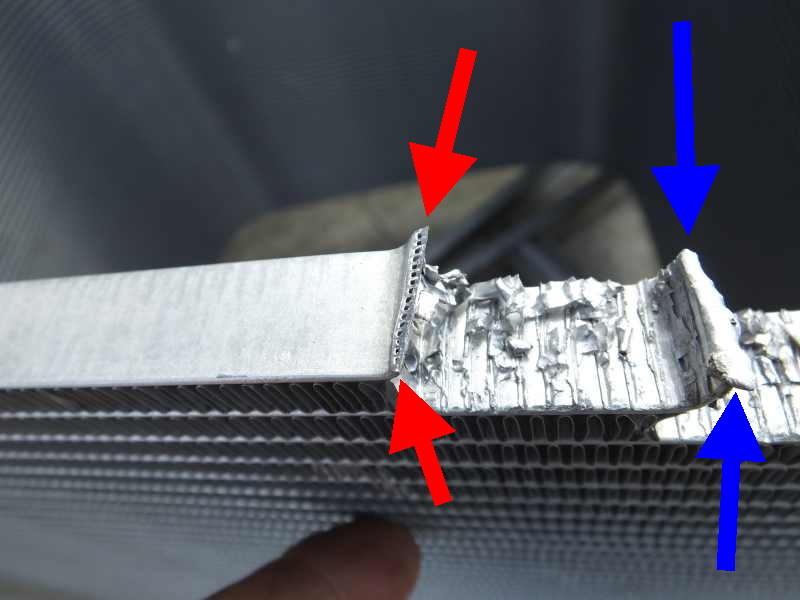

Below is the raw conditions of the damage. I will have to clean it up and force it to do some conforming for me before I can start repairing it.

1st the area between the yellow lines, must go away. So I will cut it where the red lines are. Then I need to remove the cooling fins where the blue lines are so I have some room to work in. I need to expose the 2nd coil down.

Its exposed so I can now do my magic.

I have placed a miniature delicate weld on the 2nd coil between the two blue arrows. How I did it and what I used are secrets. I can show you the end result but not how I got there. I would have to kill you if I told you how I fix the impossible radiators.

BELOW: Between the red arrows is the 1st row coil which doesn't flow Freon so it didn't need closing up. The 2nd row coil is between the blue arrows and it needed a aluminum weld to close all those miniature holes you can see in the exposed coil of row #1.

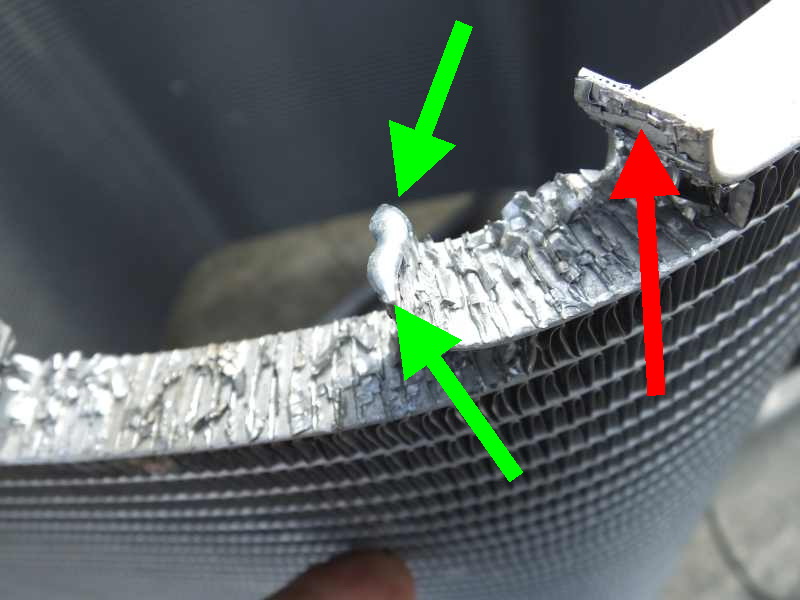

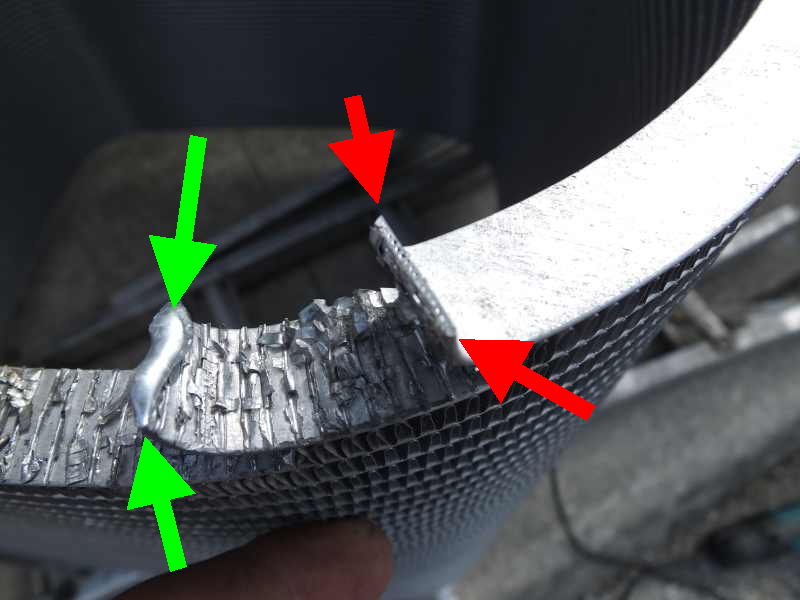

Between the green arrows is the other side of row #2 that I welded closed. The red is row #1 which was left open. For the record, that is a pure aluminum on aluminum weld. Its not solder, Its not silver solder, its not braze.

Its pure aluminum fused to pure aluminum.

Now that its welded, we do a quick pressure test to 30 PSI. It holds perfectly at 30. To test it under full pressure it must be reinstalled back into the unit. So that's next.

Now this repaired aluminum radiator is being reinstalled back in its housing.

Now comes the real pressure test. At normal operating pressure it will hold a high pressure of 250 PSI. Occasionally it will hit momentary spikes of 300 PSI very briefly.

To be sure it will hold every worst case scenario spike possible, we choose to test it to 400PSI.

Did you know your automobile radiator only holds a high pressure of 32 PSI at the maximum? And we are going to hit this Air conditioner radiator condenser with 400 PSI.

There, your looking it it holding a continuous 404 PSI for 30 minutes with zero deviation. That means no leak.

Now I have given them permission to reinstall it fully in the Ac unit and to button it all up. They are so happy. So very happy. Two weeks to order a new one would have made them look bad.

Now they have all the pipes silver soldered back together, and the wring reinstalled.

This system is now recharged with Freon and you can see the repaired radiator is 100% dry as it should be.

Oh, by the way. Freon is thinner than air or water. It can leak where water and air cannot leak.

Now these happy men are going at it full bore. They aim to have it making cold air in less than 30 minutes from now.

They still have to install the fan on top of the condenser.

For your radiator repair, AC coil, heat exchanger repair, call After Hours Welding in St Augustine Jacksonville. Save money and come to me, or my mobile radiator repair service can come to you. |

Remember, I work by appointment only, so be sure to call and schedule us. 904-638-8338 Call me, 8 Am to 9 Pm, any day of the week.

Questions or comments, feel free to call.

Our company name is "After Hours Welding & Trailer Repair." We serve all of St Johns County and surrounding areas.

We do very low-priced, competent & quality work, by appointments only any day of the week. Yes weekends and holidays to.

Call anytime thanks to the magic of cell phones, I probably am available to answer you're questions.

Without hesitation, call me at 904-638-8338 I'll be happy to give you the information

needed in order for you to make a wise, informed purchasing decision.

|

St Augustine Florida

St Augustine Florida

St Augustine Florida

St Augustine Florida