BEFORE:

AFTER:

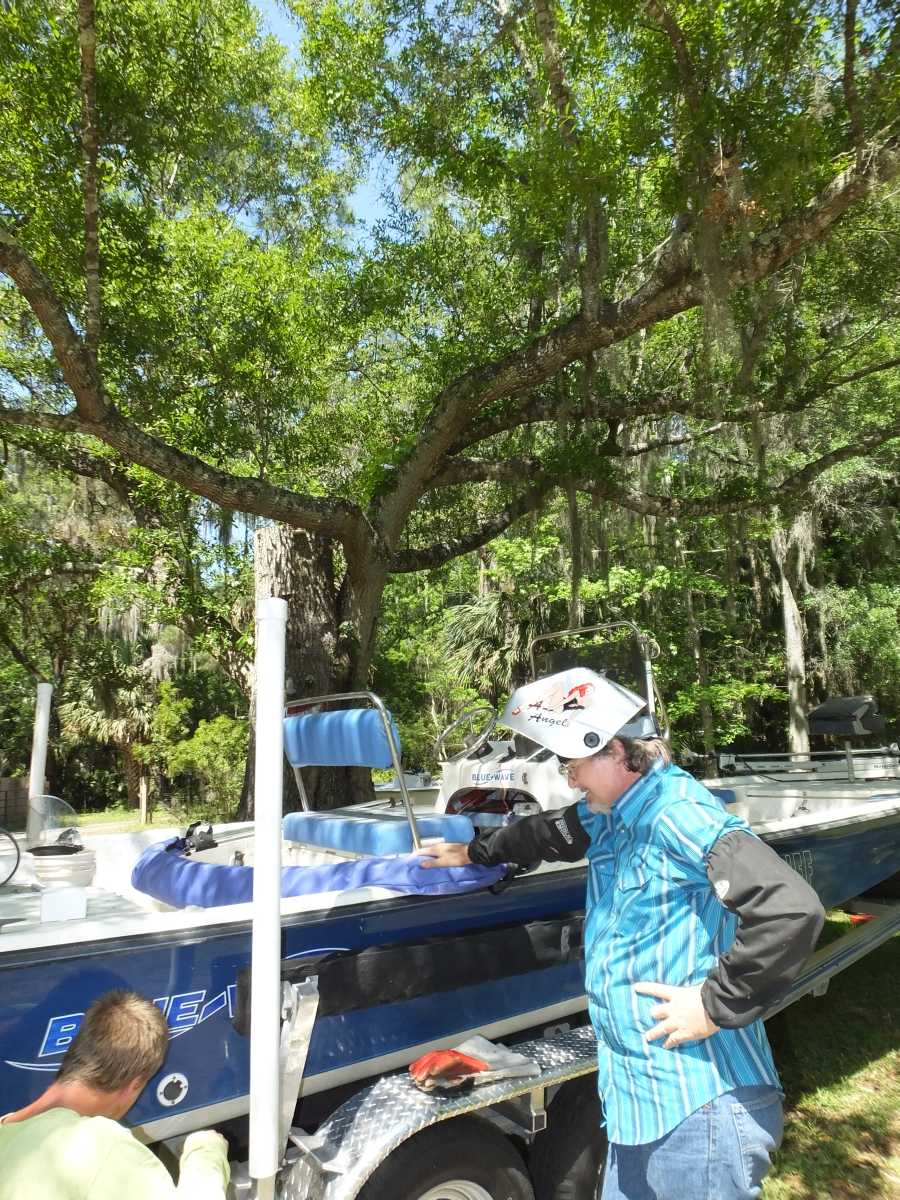

This boat was too heavy for its trailer. It is a double walled boat filled with insulation so it cant sink. This boat really needed to be on a double axle trailer and have brakes which it didn't have before.

So off comes the old worn out axle ready for a new pair.

Of course that mandated new double wheel fenders also. We are laying out the new fender to get an idea of how things will have to lay out to all fit.

We are temporarily clamping in the new axle as we check the layout and spacing we have to deal with.

We've got the spacing perfect and now they are bolted in place. But we still have a long way to go.

ABOVE: Notice the crack at the rear of the frame. It is literally splitting the I Beam at the bottom where the tail light wires come through. It will need welding and reinforcing.

The boat guide poles and horizontal bunk beam boards had to go so they could be rebuilt much stronger than before. Two out of the four connections had already failed so no point using the same design that already failed. Time for new.

He is remounting the steps where the outside of the fender will lay. You can see the first one in front of the front tire. Originally they were only bolted in and they wiggled way to much. So we will weld them in also.

Now we welded in new aluminum supports to hold the horizontal bunk boards so they are 3 times stronger than before. You will see close ups of them farther down below this page.

Freshly welded but still sooty. A wire brush will knock of the welding soot. And if you look close you can see the crack in the frame is welded closed and the rear of the frame now has a strong support cap welded on its end so the problem cant come back.

Yes those new support gussets will be cut flush with the frame.

Now you get a close up of the end cap and crack welded closed. We didn't just put down bead over the crack. We grind the crack open fully so we can weld all the way through the frame and get full penetration and maximum strength as we close it back up.

The frame is only 1/4" thick but every extra piece of support we add is 3/8" thick. If 1/4" was not holding up to start with, then why use 1/4" to replace it? NO.

We use much stronger as replacement or reinforcement pieces. We fix it so it will stay fixed.

We had to widen the supports so a double fender could fit inside.

The fender is clamped in ready for Weld attachment. Our customer asked us if we could make the fender strong enough that he could always safely climb on it and not brake it. So NOTICE between the tires we are adding below fender support that comes straight from the frame.

Now you can get a good look at the new below fender support welded directly to the frame. We used 2"x2"x1/4" thick. Super strong. And look at the rear of the fender, how its also attacked to the bunk board upright for more strength and it acts as a half step to help him climb up on.

Now you can see the step is welded to the frame whereas before it was not. And the fender is welded to the step whereas before it was not either. This is all going back together 3 times stronger than it was previously.

Now is a perfect view of the below fender support we added making it super strong and safe as step. And you can see we have added brake disks to the front axle.

Now you can see the half step between the low step and top of the fenders as its attached to the upright.

It also takes all the strength from the upright and loans it to the fender when needed. Or you could say the fender strength makes the upright stronger. They reinforce each other.

Below: you can see the fender is welded to the upright. Again making each other stronger.

Now we are welding on the tail light brackets to the frame.

Before we weld in this aluminum tail light bracket to the frame, we are pre-heating the metal with a propane torch so we don't get a cold start on the weld. It gives us great penetration from the very start.

To finish the back side of the welded joint, I have to lay under the trailer and weld overhead. These are the welds that most other welding shops skip.

I really like doing quality work. It fills me with deep satisfaction.

Now we added the white boat guides to it.

Now we are adding the hydraulic surge brake actuator to the tongue.

Soldering wires together. I refuse to use crimp on connections on boat trailers. With the corrosive environment crimp ons don't last but a few years. But soldering lasts forever.

Same as the other side.

Now we are wiring on a new 7 way plug so the trucks back up lights can energize the electric solenoid lock out valve so the truck can back up the trailer without the trailer brakes being actuated.

I'm teaching my helper how to solder lugs on wires effectively.

Ok, all done. This trailer and happy customer went on home. He was so happy to finally have brakes on his trailer and another axle, and fenders strong enough he can safely climb on. I really like making happy customers. It makes me happy. I like getting paid to make people happy. Its a great job. |  St Augustine Florida

St Augustine Florida

St Augustine Florida

St Augustine Florida